Let me start out by saying, When I installed the boosterplug I really enjoyed it, it did seem to smooth the throttle a bit. However, I noticed by smell and looking at the exhaust that I was definitely running rich in some areas. I took it off for a service, and never put it back on. I didn't miss it when I removed it. Barely even noticed.

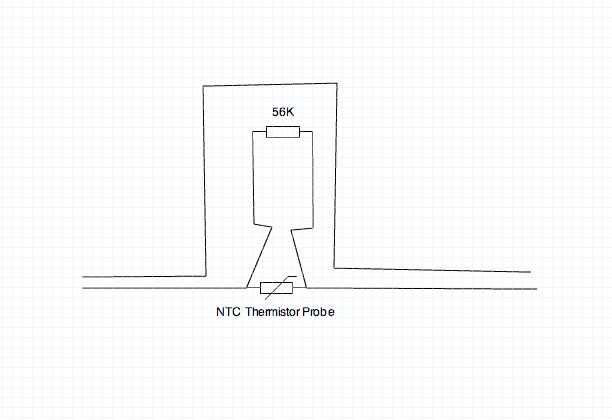

So i'm a nerd as many well know, and with some previous discussions on here I wanted to find out exactly what this thing is and how it works for the $150 price point. Well, it's pretty much as simple as I assumed. One serial resistor hooked in parallel with an NTC Thermistor probe. The resistor is a 56K Ohm resisitor, i'm not yet sure on the specs of the probe. It's all hooked together with a simple small 40 hole breadboard.

Here's the circuit in all it's glory, obviously the open ends are the temp sensor and the cable previously hooked to it. I believe the serial resistor in parallel is to compensate for when it's EXTREMELY cold and the resistance of the NTC Thermistor probe would be too high.

![Image]()

for those that don't know, in a Negative Temperature Coefficient (NTC) Thermistor the resistance decreases with increasing temperature. This is how the Boosterplug achieves it's ambient temperature compensation.

Here it is. As you can see it's not a printed circuit board, just simple hobby style board.

![Image]()

![Image]()

![Image]()

![Image]()

So what am I saying? Well, for one it would be SUPER easy to make your own one of these if I knew the specs on the NTC Thermistor.

Pricing you're looking at (US $ here)

board: $1

56K Ohm Serial Resistor: $1

NTC Thermistor probe: $10

Bosch EV1 connectors: $10

Total: $22

Now, how does this compare to other MUCH cheaper units?

here's the accelerator unit for $63 US (48Euro)

![Image]()

From what I can see, it uses a similar if not identical NTC thermistor probe as the boosterplug. THe only difference that I can see from this picture is that the Accelerator may not be using a serial resisitor in parallel, though it easily could be hidden in that wiring. I've emailed the company asking about it and for any further clarification of the difference between the Boosterplug and the Accelerator. I'll let you know what I find out!

However, this is from the Accelerator's site

/geek over and out.

So i'm a nerd as many well know, and with some previous discussions on here I wanted to find out exactly what this thing is and how it works for the $150 price point. Well, it's pretty much as simple as I assumed. One serial resistor hooked in parallel with an NTC Thermistor probe. The resistor is a 56K Ohm resisitor, i'm not yet sure on the specs of the probe. It's all hooked together with a simple small 40 hole breadboard.

Here's the circuit in all it's glory, obviously the open ends are the temp sensor and the cable previously hooked to it. I believe the serial resistor in parallel is to compensate for when it's EXTREMELY cold and the resistance of the NTC Thermistor probe would be too high.

for those that don't know, in a Negative Temperature Coefficient (NTC) Thermistor the resistance decreases with increasing temperature. This is how the Boosterplug achieves it's ambient temperature compensation.

Here it is. As you can see it's not a printed circuit board, just simple hobby style board.

So what am I saying? Well, for one it would be SUPER easy to make your own one of these if I knew the specs on the NTC Thermistor.

Pricing you're looking at (US $ here)

board: $1

56K Ohm Serial Resistor: $1

NTC Thermistor probe: $10

Bosch EV1 connectors: $10

Total: $22

Now, how does this compare to other MUCH cheaper units?

here's the accelerator unit for $63 US (48Euro)

From what I can see, it uses a similar if not identical NTC thermistor probe as the boosterplug. THe only difference that I can see from this picture is that the Accelerator may not be using a serial resisitor in parallel, though it easily could be hidden in that wiring. I've emailed the company asking about it and for any further clarification of the difference between the Boosterplug and the Accelerator. I'll let you know what I find out!

However, this is from the Accelerator's site

So it seems their unit IS designed to compensate at extreme colds, so there might be a serial resistor in there somewhere.

/geek over and out.